Polypropylene wheels are made of polypropylene, an ideal material for high volume and low cost wheel fabrication. Available in wheel sizes 2.5-8 Inches, these wheels are fracture resistant, noise and vibration dampening, have a high load capacity (80-400 Kgs) and cost less than similar wheel materials. No matter the type of chemicals found in industrial environments, PP wheels can withstand exposure to all (acids, alkalis, oils and other harsh solvents).

This resistance to corrosion and chemicals is one of the key factors that make polypropylene castors ideal for usage in various environments where chemical exposure is prevalent. These environments include manufacturing facilities, medical settings, laboratories and food processing plants. Furthermore, the lightweight yet sturdy nature of the wheel enables them to support and move heavy loads.

Material handling carts, dollies, furniture and medical equipment are some common PP wheel applications across industries. So, whether you need to transport goods in a warehouse, move medical equipment in a hospital or roll furniture in a home, polypropylene castor wheels are all you need!

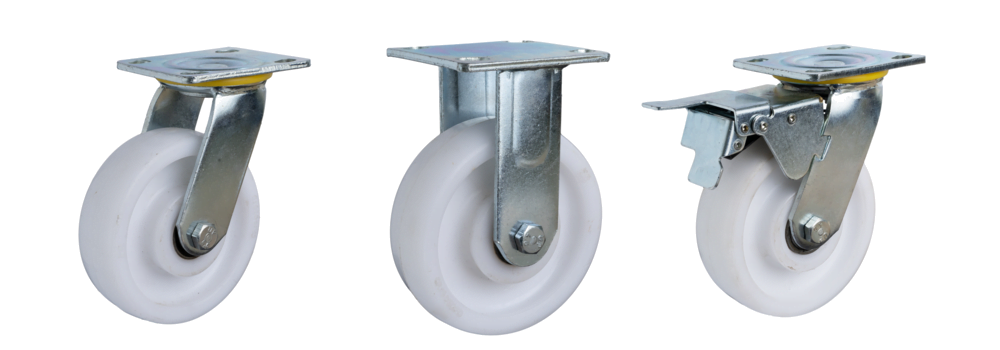

| Product code | Swivel Radius | Wheel Size | Total Height | Plate Size | Stem Height | Hole Pitch | Hole Size | Load Capacity |

|---|---|---|---|---|---|---|---|---|

| PSTS F 50 26 PPB | NA | 50x26mm | 74mm | 70x51mm | NA | 52x35mm | 8.5x11mm | 50Kgs |

| PSTS S 50 26 PPB | 50mm | 50x26mm | 74mm | 70x51mm | NA | 52x35mm | 8.5x11mm | 50Kgs |

| PSTS B 50 26 PPB | 85mm | 50x26mm | 74mm | 70x51mm | NA | 52x35mm | 8.5x11mm | 50Kgs |

| PSTS BT 50 26 PPB | 50mm | 50x26mm | 74mm | NA | 25mm | NA | NA | 50Kgs |

| PSTS BTBK 50 26 PPB | 85mm | 50x26mm | 74mm | NA | 25mm | NA | NA | 50Kgs |

| PSTS F 65 32 PPB | NA | 65x32mm | 91.5mm | 94x64mm | NA | 73x45mm | 8.5x11mm | 70Kgs |

| PSTS S 65 32 PPB | 71mm | 65x32mm | 91.5mm | 94x64mm | NA | 73x45mm | 8.5x11mm | 70Kgs |

| PSTS B 65 32 PPB | 114mm | 65x32mm | 91.5mm | 94x64mm | NA | 73x45mm | 8.5x11mm | 70Kgs |

| PSTS F 75 32 PPB | NA | 75x32mm | 103mm | 94x64mm | NA | 73x45mm | 8.5x11mm | 100Kgs |

| PSTS S 75 32 PPB | 75mm | 75x32mm | 103mm | 94x64mm | NA | 73x45mm | 8.5x11mm | 100Kgs |

| PSTS B 75 32 PPB | 114mm | 75x32mm | 103mm | 94x64mm | NA | 73x45mm | 8.5x11mm | 100Kgs |

| PSTS BT 75 32 PPB | 75mm | 75x32mm | 103mm | NA | 30mm | NA | NA | 100Kgs |

| PSTS BTBK 75 32 PPB | 114mm | 75x32mm | 103mm | NA | 30mm | NA | NA | 100Kgs |

| PSTS F 100 32 PPB | NA | 100x32mm | 130mm | 94x64mm | NA | 73x45mm | 8.5x11mm | 130Kgs |

| PSTS S 100 32 PPB | 85mm | 100x32mm | 130mm | 94x64mm | NA | 73x45mm | 8.5x11mm | 130Kgs |

| PSTS B 100 32 PPB | 114mm | 100x32mm | 130mm | 94x64mm | NA | 73x45mm | 8.5x11mm | 130Kgs |

| PSTS BT 100 32 PPB | 85mm | 100x32mm | 130mm | NA | 30mm | NA | NA | 130Kgs |

| PSTS BTBK 100 32 PPB | 114mm | 100x32mm | 130mm | NA | 30mm | NA | NA | 130Kgs |

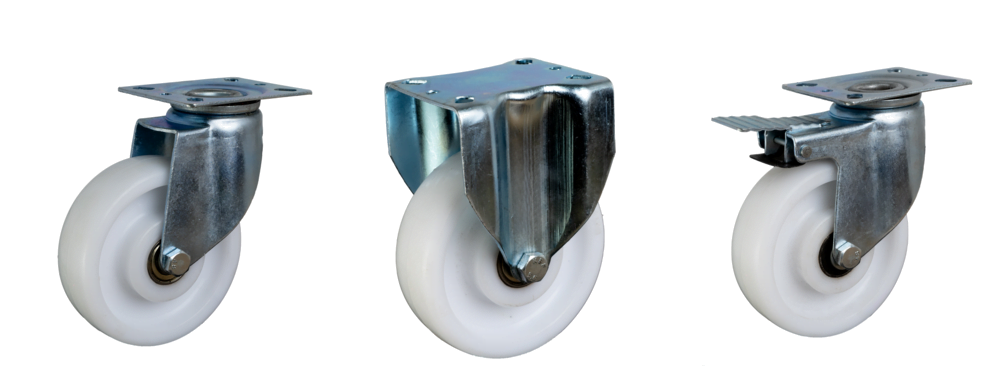

| Product code | Swivel Radius | Wheel Size | Total Height | Plate Size | Stem Height | Hole Pitch | Hole Size | Load Capacity |

|---|---|---|---|---|---|---|---|---|

| PSTP F 100 40 PPB | NA | 100x40mm | 135mm | 100x82mm | NA | 75x55mm | 15x11mm | 180Kgs |

| PSTP S 100 40 PPB | 88mm | 100x40mm | 135mm | 100x82mm | NA | 75x55mm | 15x11mm | 180Kgs |

| PSTP B 100 40 PPB | 114mm | 100x40mm | 135mm | 100x82mm | NA | 75x55mm | 15x11mm | 180Kgs |

| PSTP F 150 40 PPB | NA | 150x40mm | 190mm | 112x100mm | NA | 85x72mm | 15x11mm | 250Kgs |

| PSTP S 150 40 PPB | 118mm | 150x40mm | 190mm | 112x100mm | NA | 85x72mm | 15x11mm | 250Kgs |

| PSTP B 150 40 PPB | 130mm | 150x40mm | 190mm | 112x100mm | NA | 85x72mm | 15x11mm | 250Kgs |

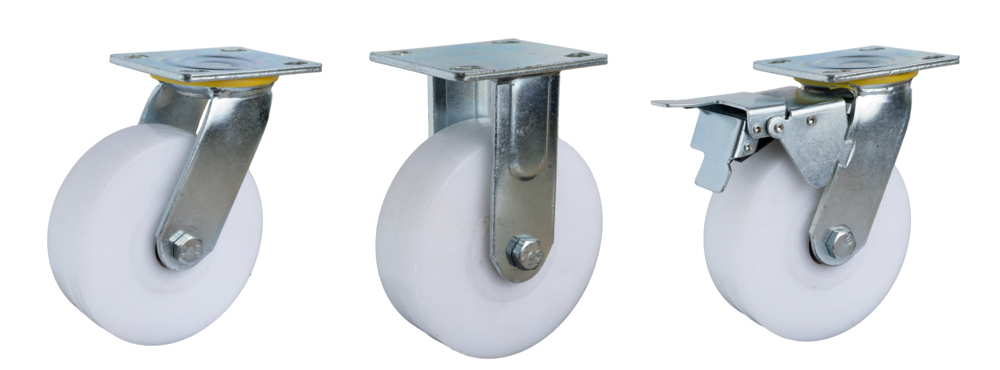

| Product code | Swivel Radius | Wheel Size | Total Height | Plate Size | Stem Height | Hole Pitch | Hole Size | Load Capacity |

|---|---|---|---|---|---|---|---|---|

| MFTP F 150 50 PPB | NA | 150x50mm | 192mm | 116x100mm | NA | 85x70mm | 20x13mm | 280Kgs |

| MFTP S 150 50 PPB | 109mm | 150x50mm | 192mm | 116x100mm | NA | 85x70mm | 20x13mm | 280Kgs |

| MFTP B 150 50 PPB | 144mm | 150x50mm | 192mm | 116x100mm | NA | 85x70mm | 20x13mm | 280Kgs |

| MFTP F 200 50 PPB | NA | 200x50mm | 242mm | 116x100mm | NA | 85x70mm | 20x13mm | 300Kgs |

| MFTP S 200 50 PPB | 153mm | 200x50mm | 242mm | 116x100mm | NA | 85x70mm | 20x13mm | 300Kgs |

| MFTP B 200 50 PPB | 158mm | 200x50mm | 242mm | 116x100mm | NA | 85x70mm | 20x13mm | 300Kgs |

| Product code | Swivel Radius | Wheel Size | Total Height | Plate Size | Stem Height | Hole Pitch | Hole Size | Load Capacity |

|---|---|---|---|---|---|---|---|---|

| HDF F 150 50 PPB | NA | 150x50mm | 205mm | 150x112mm | NA | 120x60mm | 13mm | 350Kgs |

| HDF S 150 50 PPB | 130mm | 150x50mm | 205mm | 150x110mm | NA | 120x60mm | 26x14mm | 350Kgs |

| HDF B 150 50 PPB | 163mm | 150x50mm | 205mm | 150x110mm | NA | 120x60mm | 26x14mm | 350Kgs |

| HDF F 200 50 PPB | NA | 200x50mm | 254mm | 150x112mm | NA | 120x60mm | 13mm | 450Kgs |

| HDF S 200 50 PPB | 151mm | 200x50mm | 254mm | 150x110mm | NA | 120x60mm | 26x14mm | 450Kgs |

| HDF B 200 50 PPB | 187mm | 200x50mm | 254mm | 150x110mm | NA | 120x60mm | 26x14mm | 450Kgs |

| Product code | Swivel Radius | Wheel Size | Total Height | Plate Size | Stem Height | Hole Pitch | Hole Size | Load Capacity |

|---|---|---|---|---|---|---|---|---|

| PSTIL F 150 50 PPB | NA | 150x50mm | 194mm | 115x102mm | NA | 90x64mm | 16x11mm | 150Kgs |

| PSTIL S 150 50 PPB | 110mm | 150x50mm | 194mm | 120x95mm | NA | 90x64mm | 16x11mm | 150Kgs |

| PSTIL B 150 50 PPB | 135mm | 150x50mm | 194mm | 120x95mm | NA | 90x64mm | 16x11mm | 180Kgs |

| PSTIL F 200 50 PPB | NA | 200x50mm | 249mm | 115x102mm | NA | 90x64mm | 16x11mm | 180Kgs |

| PSTIL S 200 50 PPB | 144mm | 200x50mm | 249mm | 120x95mm | NA | 90x64mm | 16x11mm | 180Kgs |

| PSTIL B 200 50 PPB | 147mm | 200x50mm | 249mm | 120x95mm | NA | 90x64mm | 16x11mm | 180Kgs |

| Product code | Swivel Radius | Wheel Size | Total Height | Plate Size | Stem Height | Hole Pitch | Hole Size | Load Capacity |

|---|---|---|---|---|---|---|---|---|

| MFTP F 100 50 PPB(S) | NA | 100x50mm | 142mm | 116x100mm | NA | 85x70mm | 20x13mm | 230Kgs |

| MFTP S 100 50 PPB(S | 74mm | 100x50mm | 142mm | 116x100mm | NA | 85x70mm | 20x13mm | 230Kgs |

| MFTP B 100 50 PPB(S) | 145mm | 100x50mm | 142mm | 116x100mm | NA | 85x70mm | 20x13mm | 230Kgs |

| MFTP F 150 50 PPB(S) | NA | 150x50mm | 192mm | 116x100mm | NA | 85x70mm | 20x13mm | 280Kgs |

| MFTP S 150 50 PPB(S) | 109mm | 150x50mm | 192mm | 116x100mm | NA | 85x70mm | 20x13mm | 280Kgs |

| MFTP B 150 50 PPB(S) | 147mm | 200x50mm | 249mm | 120x95mm | NA | 90x64mm | 16x11mm | 180Kgs |

| Product code | Swivel Radius | Wheel Size | Total Height | Plate Size | Stem Height | Hole Pitch | Hole Size | Load Capacity |

|---|---|---|---|---|---|---|---|---|

| HDF F 100 50 PPB(S) | NA | 100x50mm | 158mm | 150x112mm | NA | 120x60mm | 13mm | 250Kgs |

| HDF S 100 50 PPB(S) | 91mm | 100x50mm | 158mm | 150x110mm | NA | 120x60mm | 26x14mm | 250Kgs |

| HDF B 100 50 PPB(S) | 155mm | 100x50mm | 158mm | 150x110mm | NA | 120x60mm | 26x14mm | 250Kgs |

| HDF F 150 50 PPB(S) | NA | 150x50mm | 205mm | 150x112mm | NA | 120x60mm | 13mm | 350Kgs |

| HDF S 150 50 PPB(S) | 130mm | 150x50mm | 205mm | 150x110mm | NA | 120x60mm | 26x14mm | 350Kgs |

| HDF B 150 50 PPB(S) | 163mm | 150x50mm | 205mm | 150x110mm | NA | 120x60mm | 26x14mm | 350Kgs |

| HDF F 200 50 PPB(S) | NA | 200x50mm | 254mm | 150x112mm | NA | 120x60mm | 13mm | 450Kgs |

| HDF S 200 50 PPB(S) | 151mm | 200x50mm | 254mm | 150x112mm | NA | 120x60mm | 26x14mm | 450Kgs |

| HDF B 200 50 PPB(S) | 187mm | 200x50mm | 254mm | 150x110mm | NA | 120x60mm | 26x14mm | 450Kgs |

| Product code | Swivel Radius | Wheel Size | Total Height | Plate Size | Stem Height | Hole Pitch | Hole Size | Load Capacity |

|---|---|---|---|---|---|---|---|---|

| PSTIL F 100 50 PPB(S | NA | 100x50mm | 140mm | 95x95mm | NA | 70x70mm | 16x11mm | 130Kgs |

| PSTIL S 100 50 PPB(S) | 91mm | 100x50mm | 140mm | 95x95mm | NA | 70x70mm | 16x11mm | 130Kgs |

| PSTIL B 100 50 PPB(S) | 155mm | 100x50mm | 140mm | 95x95mm | NA | 70x70mm | 16x11mm | 130Kgs |

| PSTIL F 150 50 PPB(S) | NA | 150x50mm | 194mm | 115x102mm | NA | 90x64mm | 16x11mm | 150Kgs |

| PSTIL S 150 50 PPB(S) | 116mm | 150x50mm | 194mm | 120x95mm | NA | 90x64mm | 16x11mm | 150Kgs |

| PSTIL B 150 50 PPB(S) | 136mm | 150x50mm | 194mm | 120x95mm | NA | 90x64mm | 16x11mm | 150Kgs |

| PSTIL F 200 50 PPB(S) | NA | 200x50mm | 249mm | 102x115mm | NA | 90x64mm | 16x11mm | 180Kgs |

| PSTIL S 200 50 PPB(S | 144mm | 200x50mm | 249mm | 95x120mm | NA | 90x64mm | 16x11mm | 180Kgs |

| PSTIL B 200 50 PPB(S) | 147mm | 200x50mm | 249mm | 95x120mm | NA | 90x64mm | 16x11mm | 180Kgs |

The wheels made from polypropylene (a thermoplastic polymer) are called polypropylene wheels. Limited rolling resistance, affordability and ability to withstand harsh environments make PP castor wheels a great fit for diverse industries.

The best thing about these wheels is that their construction is durable, non staining and corrosion resistant to a wide variety of outdoor and indoor substances. Featuring 92-95 Shore A Hardness, PP wheels have a suitable temperature range from 55° to 80° Celsius.

Here are some more characteristics or exceptional properties of polypropylene castor wheels:

Polypropylene is undoubtedly one of the best wheel materials. Its unique blend of durability and lightweight nature makes it an excellent choice for a wide range of applications in the manufacturing, food processing and logistics industries. Not only does this wheel material maintain low friction, but it also offers smooth movements. Moreover, polypropylene has non-marking properties and is resistant to many chemicals, organic solvents and corrosive substances. It means the wheel leaves minimal marks on the floor and offers longevity in various environments.

Heavy duty polypropylene castor wheels are wheels specifically designed for heavy weight applications. In other words, these wheels are ideal for the most demanding working conditions because the wheel bearings are designed to improve the resistance capacity of the wheels. Additionally, heavy duty wheels usually go through many tests such as salt spray, fluid resistance, compression set, temperature and UV enduring tests, and more to ensure their flawlessness. As a result, many businesses appreciate heavy duty polypropylene wheels’ excellent load-bearing capacity. Typically, these types of polypropylene castors are used in material handling applications, industrial settings and manufacturing plants where excellent strength, chemical resilience and load bearing capacity are vital requirements.

Although PP wheels have a lower load capacity than nylon wheels, you can use them in many industrial settings for different applications. For example, the wheels remain in demand for hygiene requirements and resistance to chemicals in the food and pharmaceutical industry. In addition, PP wheels are used in industrial settings like manufacturing facilities and distribution centers to support and transfer heavy loads efficiently. Thanks to the polypropylene wheel’s durability and versatility, you can use them in retail environments and residential applications.

Businesses have many reasons to use polypropylene wheels. Here are some:

Yes! Since polypropylene wheels are non-toxic, odorless, chemical-resistant and FDA-approved, you can effectively use them in environments that demand hygiene, cleanliness and sanitation. These environments include food processing facilities, commercial kitchens and catering equipment.

Cleaning polypropylene castor wheels every day is enough to remove dirt and debris and keep the wheels in good condition. That means that these wheels require very minimal maintenance. But remember, the maintenance also depends on the application and environment. Sometimes the wheels may demand occasional lubrication and periodic inspections to check for wear and tear and function smoothly. Overall, PP wheels are known for their resistance to chemicals, corrosion and moisture, thus reducing the need for extensive maintenance. These qualities make polypropylene wheels convenient for different commercial and industrial applications.

Although polypropylene is a recyclable material, the eco-friendliness of the wheel depends on several factors. Some manufacturers contribute to environmental conservation by offering wheels made from recycled polypropylene. In addition, PP wheels’ durability and resistance to chemicals and corrosion add to their lifespan, thus reducing the need for frequent replacements and waste generation. However, consider the wheels’ entire lifecycle from production to disposal as it is the only way to access its overall eco-friendliness.

Choosing the right polypropylene wheel is necessary to ensure operational efficiency, safety and your equipment’s running cost. Load capacity, application environment (indoors, outdoors or specialized conditions), wheel diameter, wheel type (rigid or swivel castors), bearing type and compatibility (between the wheel’s mounting method and your equipment) are some factors you should consider when choosing a polypropylene wheel to satisfy your unique needs and increase your material handling operation’s efficiency.

There is no fixed lifespan of polypropylene wheels as it depends on various factors like usage frequency, load capacity, maintenance and environmental conditions. If you clean these wheels daily and maintain them properly, you can even make them last for years. On the other hand, utilizing them in harsh environments can result in a shorter lifespan.